Non-Woven Industries Development. Non-woven fabric was invented in the petrochemical industry following the development of plastic cloth (film). It weighs less than plastic cloth, and has greater ventilation. It is used extensively in personal and medical hygiene products, like filters, facial towels, and disposable napkins for sanitary use. Later, the technology was further developed, and later utilized in engineering. Non-woven fabric protects the crops of vegetables from damage from cold. The manufacturing process of non-woven fabric is different from plastic film, however the basic raw materials are nearly the same. This includes PVC (polyvinyl chloride) PET (polyethylene), EVA [Ethylene Vinyl Acetate copolymer], PVA (polyvinyl alcohol) and so on. Inflating traditional plastic film with heat, it produces thin film. The film is continuous and can be extended for a long time. The film's surface is free of pores. The film is impermeable , and prevents any movement or exchange of molecules. Artificial chemical fibers derived from the mentioned sources became the most popular choice for the textile industry following the growth of the manufacturing industry. These chemical fibers, however can be converted into cloth using traditional warp-weft weaving. The non-woven material is made by connecting fibers in the same plane and at different angles across all directions. It is not possible to utilize traditional warp and weave methods. It's more durable than traditional woven fabric and can be made from raw materials in just one day. It's cheaper than traditional weaving, which requires weaving yarn into fibers and then weaving. Recent years have seen the widest range of non-woven fabrics used in the clothing industry. Thanks to advances in the field of materials science, as well as the development and application of production technology, nonwoven fabrics have become more varied and are being employed more frequently. There are many different materials and products found in everyday life. The increasing use of non-woven textiles in agriculture is mainly due to their lightweight, simple production, cost-effective diversification, and wide variety of uses. Follow this non woven weed control fabric for more info.

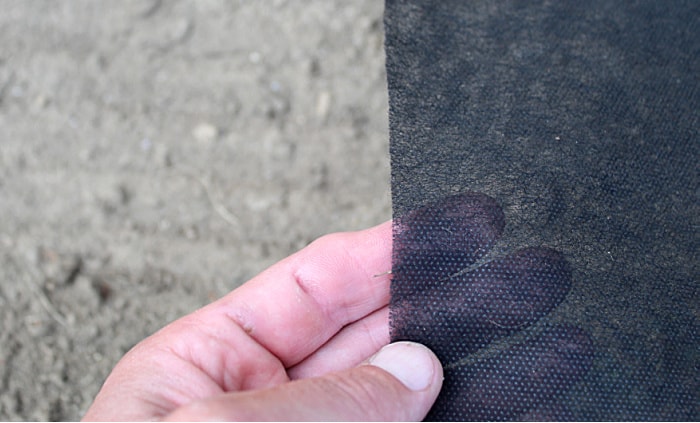

Non-woven Fabrics in Agriculture. Non-woven textiles were first introduced to agriculture in Europe in 1978. They can be used to keep carrots warm in the beginning of harvesting, and to protect against the ravages of whiteflies and tomato leaf viruses. Non-woven fabrics in the United States are used for mulching sweet peppers, cantaloupes tomatoes and root vegetables. They are used to conserve temperatures, facilitate early harvesting and also to combat insects. Since non-woven materials are able to raise the temperature of soil and also have a high water retention, they are used for surfaces like grass-proof mats. Short fibers are used to create water-absorbing blankets that are placed on nursery beds in order to allow the roots to fully absorb water. They can serve as the base medium to produce turf or garden grassland to moisturize drain, divide, and spruce up the garden. They are also used as planters for large woody plants like fruit trees and trees for gardens to prevent weeds from growing and also for retaining the moisture. Non-woven fabric can also be utilized as crop covers in Taiwan. They are also used extensively to cut down on energy use in large greenhouses. Double-layered curtains and canopy covers minimize radiation and heat at night. TAVIK fabrics are high-density, non-woven spunbonded TAVIK fabrics utilized in the beginning for shading and protecting cauliflower bulbs. Because of its superior shading capacity, lower thermal conductivity as well as its easy recycleability, it quickly adopted by farmers. It was then used in the preservation of shade and preservation of leafy vegetables as in the cultivation and protection of pineapples and fruit trees. The development of non-woven industries has been slow due to Taiwan's unique climate and ecology. Taiwan's non-woven fabric producers continue to develop non-woven technologies. They are focusing on air permeability and water absorption and water repellency. It is utilized to store and preserve agricultural product. Follow this agriculture non woven fabric suppliers for tips.